Top Trends in Pack Machinery for 2025: What to Expect and How to Prepare

As the landscape of manufacturing continues to evolve, the field of pack machinery is no exception. With rapid advancements in technology and an increasing focus on sustainability, understanding the top trends in pack machinery for 2025 is crucial for industry stakeholders. This article will explore the anticipated developments in pack machinery that not only enhance operational efficiency but also address the growing demand for environmentally friendly practices.

In pack machinery, automation, smart technologies, and sustainable materials are set to take center stage, reshaping how products are packaged and delivered. As companies strive to meet consumer expectations for faster, more reliable packaging solutions, the integration of artificial intelligence and machine learning into machinery will become more prevalent. Additionally, the emphasis on reducing waste and optimizing resources will drive innovations in eco-friendly materials and processes. This comprehensive overview aims to equip businesses with the knowledge necessary to navigate the future landscape of pack machinery, ensuring they remain competitive and responsive to market changes.

Emerging Technologies in Packaging Machinery for 2025

As we look ahead to 2025, the landscape of packaging machinery is set to evolve dramatically, driven by emerging technologies that promise to enhance efficiency and adaptability. Advancements in automation and artificial intelligence are becoming pivotal, allowing packaging systems to operate with minimal human intervention while maintaining precision and speed. Enhanced machine learning algorithms will enable equipment to analyze production data in real-time, leading to smarter decision-making processes that can optimize workflow and reduce downtime.

Moreover, the integration of sustainable practices into packaging machinery is a growing trend that cannot be overlooked. Technologies aimed at reducing material waste and enhancing recyclability are essential as industries strive to meet environmental standards. Innovations such as biodegradable packaging solutions and energy-efficient machinery are gaining traction, reflecting a shift towards more eco-conscious production methods. This focus on sustainability, coupled with advancements in materials science, will help manufacturers to not only meet consumer demands for greener products but also adapt to future regulatory changes surrounding packaging waste.

In addition, the rise of smart packaging technologies, which incorporate sensors and IoT capabilities, is set to revolutionize the packaging industry. These features not only improve inventory management and supply chain tracking but also provide valuable data that can inform business strategies. Companies will need to prepare for these trends by investing in training for their workforce and ensuring their machinery is compatible with these advanced technologies, positioning themselves favorably in the competitive market of 2025.

Sustainability Practices Driving Pack Machinery Innovations

The push for sustainability is reshaping the landscape of packaging machinery innovations. As consumers demand more eco-friendly products and practices, manufacturers are pivoting towards technologies that reduce waste, energy consumption, and carbon footprints. This shift is prompting the integration of materials that are recyclable, biodegradable, or made from renewable sources. Companies are increasingly investing in machinery capable of utilizing these sustainable materials, ensuring that their packaging solutions align with environmental goals.

To stay ahead in this evolving market, it’s essential for businesses to adopt sustainable practices. Here are a couple of tips to help in this transition: First, consider conducting a thorough assessment of your current packaging processes to identify areas where waste can be minimized. Implementing materials that require less energy to produce can significantly lower your environmental impact. Additionally, investing in machinery that allows for flexibility in packaging design can enable the use of various sustainable materials, making it easier to adapt to new regulations and consumer preferences.

Moreover, collaboration with suppliers is crucial in ensuring access to innovative materials and technologies. Engaging in partnerships focused on sustainability can lead to groundbreaking solutions that not only enhance the efficiency of your packaging operations but also resonate with eco-conscious consumers. Emphasizing transparency in your supply chain and showcasing your commitment to sustainability can strengthen your brand’s reputation in a competitive marketplace.

Top Trends in Pack Machinery for 2025

Automation and Smart Solutions in Packaging Processes

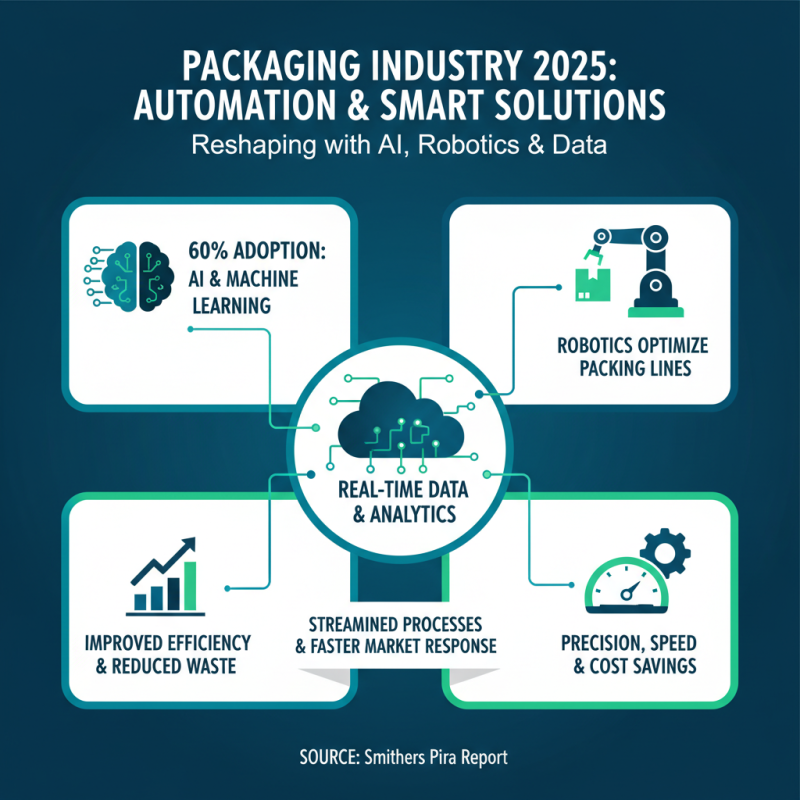

The advancements in automation and smart solutions are set to reshape the packaging industry significantly by 2025. According to a recent report by Smithers Pira, over 60% of packaging companies are expected to adopt AI and machine learning technologies to improve efficiency and reduce waste. These smart solutions allow for real-time data collection and analysis, enabling companies to streamline their processes, enhance productivity, and respond quickly to market demands. Robotics, in particular, has become integral in optimizing packing lines, as they can perform repetitive tasks with precision and speed, ultimately minimizing labor costs and human error.

**Tips:** When considering automation, start with a thorough assessment of your current processes. Identify bottlenecks and areas where technology could offer the greatest impact. Training staff on new systems will also ensure a smoother transition, maximizing the benefits of your investment.

Additionally, the integration of IoT (Internet of Things) devices into machinery is another trend anticipated to soar. These devices facilitate machine-to-machine communication, allowing for predictive maintenance and minimizing downtime. A survey from Industry Week indicated that companies implementing IoT solutions in their packaging lines could see a 20% increase in operational efficiency.

**Tips:** Prioritize your investments by focusing on technologies that align with your specific operational needs and strategic objectives. Collaborating with tech partners who understand the packaging landscape can also help you leverage the full potential of these innovations.

Customization and Flexibility Trends in Packaging Equipment

The packaging machinery sector is witnessing a significant shift towards customization and flexibility, driven by changing consumer preferences and the need for operational efficiency. According to a recent industry report, nearly 70% of packaging companies are prioritizing adaptable machinery that can handle a variety of products without the need for extensive reconfiguration or downtime. This demand for customization is rooted in the ever-increasing consumer desire for personalized products, which pushes manufacturers to adopt flexible solutions capable of producing small batch sizes with unique specifications.

Moreover, advancements in automation and digital technology are facilitating this trend. A report by a leading market research firm highlights that nearly 60% of packaging firms are investing in smart machinery that incorporates IoT capabilities, allowing for real-time adjustments and data collection. This technology not only enhances the efficiency of production lines but also supports swift changes in packaging designs and materials, catering to market demands. As companies look towards 2025, the integration of advanced data analytics and AI-driven systems in packaging machinery is set to further revolutionize how products are packaged, ensuring that flexibility and customization not only meet consumer needs but also optimize the overall supply chain.

Market Demands Shaping the Future of Packaging Machinery

As we look towards 2025, the landscape of packaging machinery is being redefined by evolving market demands. Increasing consumer preference for sustainable packaging solutions is a driving force. According to a recent report by Smithers Pira, the global market for sustainable packaging is expected to reach $400 billion by 2027, growing at a CAGR of 11.4%. This shift is prompting manufacturers to invest in machinery that not only meets production needs but also aligns with eco-friendly practices. Businesses are integrating technologies that support recyclable and biodegradable materials, thus transforming their packaging lines.

In tandem with the sustainability trend, there's a significant push for automation and smart technology within packaging machinery. A study by MarketsandMarkets indicates that the smart packaging market is projected to grow from $27 billion in 2021 to over $46 billion by 2026, an annual growth rate of 11%. This surge is attributed to the need for operational efficiency and enhanced product traceability. To remain competitive, manufacturers should consider adopting automation solutions, such as IoT-enabled machinery that collects real-time data for improved decision-making and predictive maintenance.

Tip: To effectively prepare for these trends, businesses should conduct a thorough market analysis to understand specific consumer demands in their regions. Investing in training programs for staff to operate advanced machinery can also ensure a smoother transition and maximize productivity gains.

Related Posts

-

Exploring Innovative Food Packaging Machine Types: Industry Trends and Data Insights

-

The Future of Innovative Flexible Packaging Machines for Sustainable Solutions

-

Unmatched Quality from China's Premier Factories Establishing Global Trust in the Best Wrapping Machine

-

Premier Chinese Factory Delivers Exceptional Packaging Equipment and Machinery Worldwide

-

Global Reach of Chinese Manufacturing in Best Packaging Equipment with Trusted Quality Standards

-

Unmatched Quality from Trusted Chinese Manufacturers for the Best Package Equipment