Top 10 Cartoning Equipment Solutions for Efficient Packaging Automation

In the rapidly evolving landscape of packaging automation, the role of cartoning equipment has become increasingly pivotal for businesses aiming to optimize operational efficiency and reduce costs. Reports from industry analysts indicate that the global cartoning equipment market is projected to grow by 4.5% annually, reaching a valuation of approximately $4 billion by 2025. This growth underscores the importance of investing in advanced technologies that enhance speed and accuracy in packaging processes.

According to industry expert Dr. Emily Richards, a leading authority on packaging automation, “The strategic implementation of innovative cartoning equipment solutions not only streamlines production lines but also significantly elevates product presentation.” Her insights reflect a broader trend in the industry, where manufacturers are constantly seeking solutions that combine productivity with superior packaging quality. As we explore the top 10 cartoning equipment solutions for efficient packaging automation, it becomes clear that embracing such technologies is not just a trend, but a necessity for staying competitive in a demanding marketplace.

Innovative Cartoning Machines: Revolutionizing Automation in Packaging

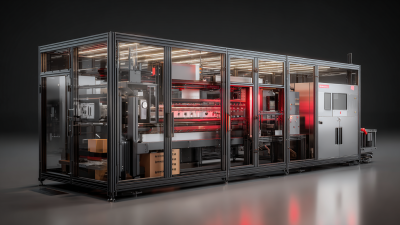

Innovative cartoning machines

are at the forefront of revolutionizing automation in packaging, driving efficiency and productivity across various industries. According to a report by Grand View Research, the global cartoning equipment market is expected to reach $5.75 billion by 2025, growing at a CAGR of 4.5%. This growth highlights the increasing demand for automated solutions that enhance operational efficiency and reduce labor costs. Companies are increasingly adopting these advanced machines to streamline their packaging processes, ensuring products are not only packaged swiftly but also securely.

The latest innovations in cartoning technology include high-speed, servo-driven systems that can adjust to fluctuating production requirements without sacrificing performance. For instance, manufacturers like A-B-C Packaging Machine Corporation have introduced machines capable of bundling, loading, and sealing products at rates exceeding 150 cartons per minute. Such efficiency is complemented by features like easy changeovers and integration with existing production lines. Industry studies indicate that businesses implementing these innovative machines can achieve up to a 30% reduction in packaging costs, proving that investing in the right automation technology is vital for maintaining a competitive edge in the marketplace.

Key Features of High-Performance Cartoning Equipment for Businesses

When considering the most efficient packaging automation solutions, high-performance cartoning equipment emerges as a crucial factor for businesses aiming to optimize their operations. Key features of such equipment include speed, flexibility, and advanced technology integration. Speed is paramount; top-tier models can handle large volumes of products quickly, reducing bottlenecks and enhancing throughput. Flexibility allows for easy adjustments to accommodate various product sizes and packaging formats, making it vital for businesses with diverse offerings.

Moreover, advanced technology integration plays a significant role in improving precision and reliability. Modern cartoning machines come equipped with smart sensors and automation capabilities that ensure consistent quality and minimize errors in the packaging process. Businesses looking to invest in cartoning solutions should prioritize equipment that offers user-friendly interfaces and seamless connectivity with other systems, enabling smooth operations from production to distribution. With the right cartoning equipment, companies can significantly enhance their packaging efficiency, ultimately contributing to their overall growth and success in the competitive market.

Top 10 Cartoning Equipment Solutions for Efficient Packaging Automation

This chart represents key performance dimensions of top cartoning equipment for efficient packaging automation. The parameters include speed in boxes per minute, accuracy percentage, ease of use rating, maintenance frequency per month, and cost in USD. Analyzing these metrics helps businesses make informed decisions on their packaging solutions.

Comparative Analysis of Top Brands in Cartoning Solutions

The landscape of cartoning equipment solutions is vast, with numerous brands offering innovative solutions aimed at optimizing packaging processes. A comparative analysis of the top brands reveals key differences in their approach to efficiency, technology integration, and customization options. For instance, Brand A focuses on high-speed operations and exceptional reliability, making it a preferred choice for large-scale manufacturers. Their machines are designed to seamlessly integrate with existing production lines, ensuring minimal downtime during operation.

On the other hand, Brand B excels in offering flexible and compact solutions, ideal for businesses with limited space or those requiring frequent changeovers for different product lines. Their equipment boasts advanced automation features that allow for quick adjustments, catering to diverse packaging needs without sacrificing speed or quality. When evaluating these brands, it's essential to consider how each company's technology aligns with specific operational requirements, enabling manufacturers to enhance productivity while maintaining cost-efficiency in their packaging processes.

Top 10 Cartoning Equipment Solutions for Efficient Packaging Automation

| Model | Speed (Cartons per Minute) | Automation Type | Features | Price Range ($) |

|---|---|---|---|---|

| Model A | 30 | Fully Automated | Versatile, Fast Changeover | 20,000 - 30,000 |

| Model B | 25 | Semi-Automated | Compact Design, User-Friendly | 15,000 - 25,000 |

| Model C | 40 | Fully Automated | High Efficiency, Energy Saving | 25,000 - 35,000 |

| Model D | 20 | Manual | Cost-Effective, Simple Operation | 5,000 - 10,000 |

| Model E | 35 | Fully Automated | Logistics Integration, Smart Control | 30,000 - 40,000 |

| Model F | 28 | Semi-Automated | Flexible, Space-Saving | 18,000 - 28,000 |

| Model G | 32 | Fully Automated | High Precision, Reduced Waste | 22,000 - 32,000 |

| Model H | 26 | Manual | Durable, Easy Maintenance | 8,000 - 15,000 |

| Model I | 33 | Fully Automated | Integrated Systems, Smart Features | 27,000 - 37,000 |

| Model J | 29 | Semi-Automated | Cost-Effective, Efficient | 16,000 - 26,000 |

Cost-Effective Cartoning Solutions: Balancing Investment and Efficiency

In today's competitive packaging landscape, businesses are increasingly seeking cost-effective cartoning solutions that strike a balance between investment and efficiency. According to a recent report from PMMI, the Association for Packaging and Processing Technologies, the global packaging machinery market is expected to grow at a CAGR of 3.7% through 2025, reaching a value of approximately $50 billion. This reflects an ongoing trend where companies recognize the importance of automating their packaging processes, minimizing labor costs while maximizing output.

Investing in modern cartoning equipment not only enhances productivity but also leads to significant long-term savings. For instance, automated carton erectors and closers can reduce packing time by up to 30%, allowing companies to respond more swiftly to market demands. Additionally, a study by Packaging Strategies found that businesses implementing semi-automated solutions reported a 25% decrease in material waste, further contributing to overall cost savings. By leveraging innovative technology, manufacturers can not only improve their packaging operations but also ensure that their investments are aligned with sustainability goals, making a compelling case for adopting advanced cartoning solutions.

Future Trends in Cartoning Technology for Enhanced Packaging Systems

The landscape of cartoning technology is evolving rapidly, driven by advances in automation and smart packaging solutions. According to the MarketsandMarkets report, the global packaging automation market is projected to reach USD 66.58 billion by 2025, growing at a CAGR of 12.7%. This growth is largely attributed to the increasing demand for efficient and flexible packaging systems. Innovative cartoning equipment that incorporates artificial intelligence and IoT capabilities is becoming essential for manufacturers looking to enhance productivity and reduce operational costs.

Emerging trends indicate a shift towards the integration of automated cartoning systems with data analytics and machine learning technologies. This transition allows for real-time monitoring and predictive maintenance, thereby minimizing downtime. A report by Allied Market Research highlights that the smart packaging segment alone is expected to witness a notable CAGR of 10.5% from 2021 to 2027. As companies strive to meet consumer demands for sustainability and customization, advanced cartoning solutions that can adapt to diverse packaging requirements will become invaluable assets in the modern packaging ecosystem.

Related Posts

-

Navigating the 2025 Trends in Best Packaging Equipment for Global Buyers to Enhance Efficiency

-

5 Essential Tips to Maximize Efficiency with Your Package Machine

-

Understanding the Unique Features and Applications of Best Cartoning Equipment for Your Packaging Needs

-

Unmatched Quality from Trusted Chinese Manufacturers for the Best Package Equipment

-

5 Compelling Reasons Your Business Needs the Best Packaging Equipment Today

-

How to Choose the Right Food Packaging Equipment for Your Business