Why Investing in a Powder Packaging Machine Can Boost Your Production Efficiency by 30 Percent

In today's fast-paced manufacturing landscape, efficiency is paramount, especially in industries dealing with powders, such as food, pharmaceuticals, and chemicals. A recent survey by the Packaging Machinery Manufacturers Institute (PMMI) indicates that companies that invest in advanced packaging technologies, such as a powder packaging machine, can improve their production efficiency by up to 30%. This significant boost not only accelerates throughput but also enhances accuracy and reduces waste, directly impacting the bottom line. As consumer demand for quick turnaround times and high-quality products continues to rise, many businesses are realizing that incorporating state-of-the-art powder packaging machines is no longer just an option but a necessity for maintaining competitive advantage in the market.

Understanding the Key Benefits of Powder Packaging Machines

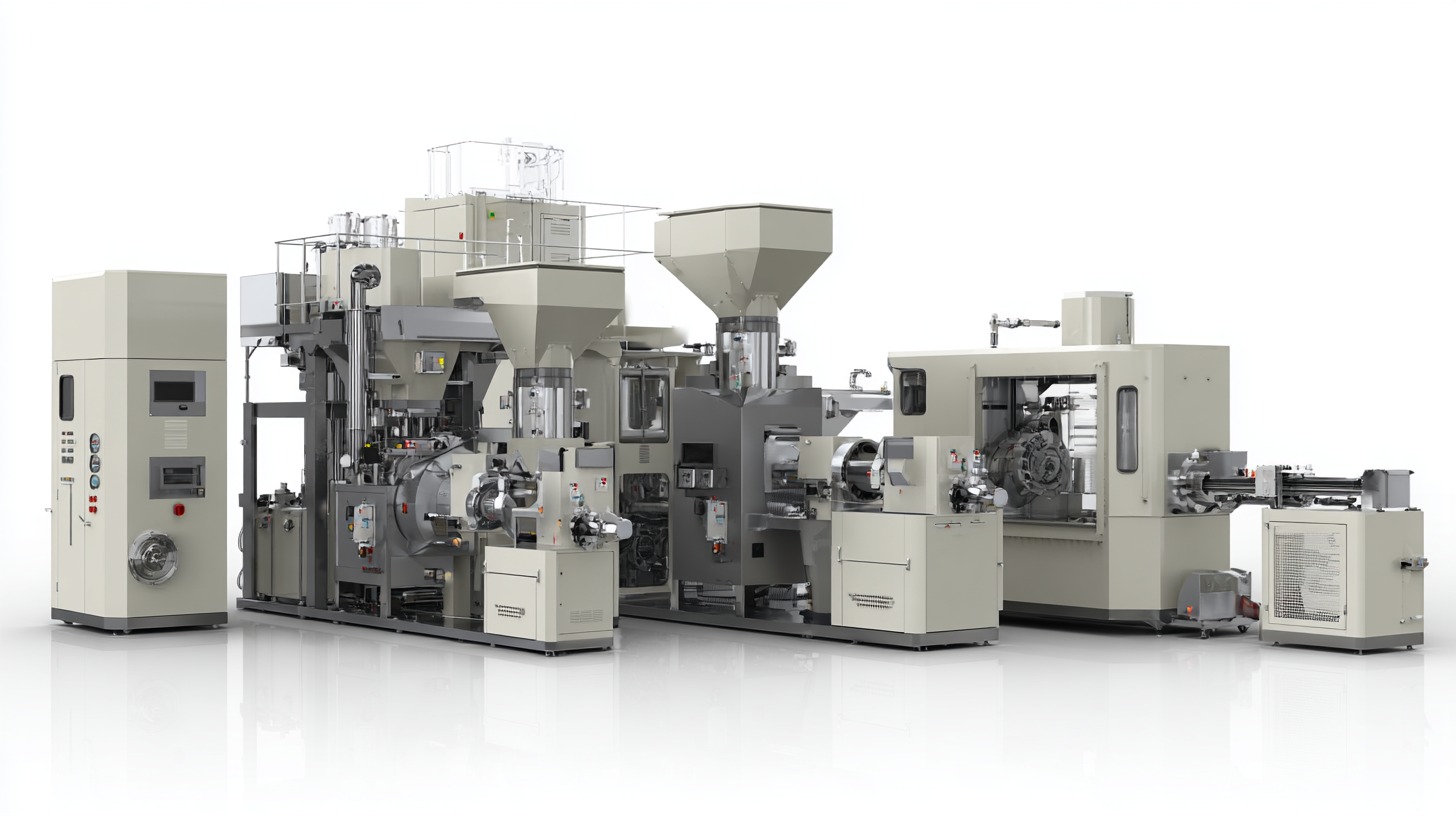

Investing in a powder packaging machine offers significant advantages that can enhance production efficiency. One of the key benefits is the streamlined packaging process. Traditional methods can be labor-intensive and time-consuming, often leading to bottlenecks in production lines. However, a powder packaging machine automates this process, reducing manual intervention and increasing throughput. This efficiency gain can result in up to a 30 percent boost in production, allowing companies to meet growing demand without the need for substantial workforce increases.

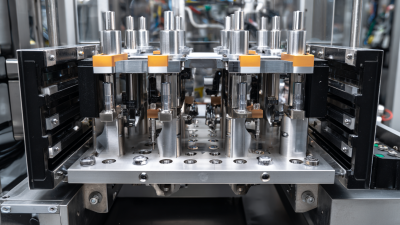

Another vital aspect to consider is the precision and consistency that powder packaging machines bring to the table. These machines are designed to ensure accurate measurements of powders, minimizing waste and product loss. This level of precision not only improves the quality of the final product but also enhances customer satisfaction. Furthermore, modern machines often come equipped with advanced technology that can accommodate various powder types and packaging sizes, making them a versatile addition to production facilities. By understanding these benefits, businesses can make informed decisions about investing in powder packaging machines for their operations.

Identifying Production Bottlenecks in Your Packaging Process

Identifying production bottlenecks in your packaging process is crucial for enhancing overall efficiency. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), up to 70% of manufacturers experience production slowdowns due to inefficient packaging processes. These slowdowns can stem from outdated equipment, inadequate workflow design, or poor integration of different packaging stages. By understanding where these bottlenecks occur, companies can make informed decisions to invest in new technologies, such as powder packaging machines, which are known to significantly streamline operations.

Investing in a modern powder packaging machine can reduce manual handling and increase accuracy, leading to an estimated 30% boost in production efficiency. For instance, a study conducted by Freedonia Group indicates that automated packaging solutions, including advanced powder filling systems, can optimize throughput and minimize waste associated with packaging errors.

Furthermore, eliminating bottlenecks not only enhances productivity but also improves employee morale, as workers can focus on more strategic tasks rather than dealing with frustrating delays. Overall, recognizing and addressing these bottlenecks is essential for any manufacturer looking to stay competitive in an increasingly demanding market.

Selecting the Right Powder Packaging Machine for Your Needs

Selecting the right powder packaging machine is crucial for enhancing production efficiency. According to a recent report by the Packaging Machinery Manufacturers Institute (PMMI), companies that utilize advanced packaging technologies can achieve efficiency improvements of up to 30%. This is particularly significant in the powder industry, where precision and speed are key. A suitable packaging machine not only ensures accurate filling but also minimizes waste, leading to substantial cost savings.

When choosing a powder packaging machine, factors such as the type of powder, required throughput, and desired packaging format should be considered. For instance, a study by Smithers Pira highlights that powdered products like pharmaceuticals or food items have unique handling requirements that must be addressed with specialized machinery. Additionally, investing in machines with automation features can reduce labor costs and increase throughput by streamlining the packaging process. In summary, making an informed choice about a powder packaging machine can significantly contribute to a company's operational efficiency and bottom-line profitability.

Implementing Automation for Enhanced Packing Speed and Accuracy

The implementation of automation in powder packaging machinery is transforming the packaging industry, significantly increasing production efficiency and accuracy. Industry reports indicate that businesses employing automated packing systems can see a productivity boost of up to 30 percent. This enhancement is driven by advanced technologies such as FFS (Form-Fill-Seal) and FBS (Fill-Bag-Seal), which are designed for high-speed operation and precise measurement. For instance, the latest FFS machines can achieve speeds of up to 1,200 packages per hour, making them essential for meeting the growing demands of various sectors including food and beverage, agriculture, and chemicals.

As the packaging industry faces challenges such as increasing safety concerns and the need for higher throughput, the shift toward automated solutions becomes indispensable. A recent analysis from the Global Industrial Robot Servo Systems Market highlights significant growth across applications, particularly in material handling and packaging. The rise in incidents involving foreign substances in food packaging underscores the importance of investing in technologies that not only enhance speed but also improve the safety and quality of packaged goods. By integrating sophisticated robotic systems into their operations, companies can not only elevate their production standards but also adapt to an ever-evolving marketplace that prioritizes efficiency and safety.

Measuring Efficiency Gains: Tracking Your Production Improvements

Investing in a powder packaging machine significantly enhances production efficiency, with some estimates suggesting an increase of up to 30 percent. This improvement can be tracked through various application performance metrics, allowing manufacturers to gain a tangible view of their operational enhancements. For instance, recent studies indicate that targeted investments in digital and data foundations are becoming crucial as manufacturers seek to innovate while addressing skill gaps and productivity challenges within their teams.

In the context of productivity measurement, the shift from traditional metrics to new benchmarks is essential. As businesses embrace new technologies, they must adopt measures that reflect the actual performance of human resources, especially as AI becomes integrated into workflows. Research highlights that organizations leveraging advanced tools can improve task completion times significantly, thereby directly impacting overall production rates. Manufacturers now have the opportunity to utilize real-time data to refine their operations continually, fostering a culture of ongoing improvement and efficiency tracking that aligns with economic growth trends.

Related Posts

-

Unlocking Efficiency with the Advantages of the Best Powder Packaging Machine

-

7 Essential Tips for Choosing the Best Coffee Packaging Equipment

-

7 Amazing Benefits of the Best Cardboard Box Machine

-

How to Optimize Your Production Line with a Doy Pack Machine for Maximum Efficiency

-

7 Essential Tips for Choosing the Best Bakery Packaging Machine to Boost Production Efficiency

-

How to Choose the Right Flexible Packaging Machines for Your Business Needs