How to Choose the Best Cardboard Box Machine for Your Packaging Needs: Insights & Trends

In today's fast-paced global market, the packaging industry is undergoing significant transformations, with the demand for efficient and high-quality solutions on the rise. As businesses aim to meet diverse consumer needs, selecting the right cardboard box machine becomes pivotal. This essential equipment not only streamlines the packaging process but also enhances the overall product presentation.

In this blog, we will explore the latest insights and trends that influence the choice of cardboard box machines, providing valuable guidance for companies looking to adapt and thrive in a competitive landscape. With a focus on quality, we will discuss how advancements in technology and manufacturing practices are enabling Chinese producers to reach international markets and secure a strong foothold globally.

Join us as we delve into the criteria for selecting the best cardboard box machine to meet your unique packaging requirements.

Understanding Your Packaging Requirements: Key Factors to Consider

When considering the purchase of a cardboard box machine, it’s crucial to understand your specific packaging requirements. Start by assessing the types of products you need to package. Are they small, lightweight items or larger, bulkier goods? This will significantly influence the type of machine you require, as different models are engineered for various sizes and weights. Additionally, consider the frequency and volume of production. If high-volume packaging is essential for your operations, opt for a machine that can handle heavy-duty tasks efficiently.

Next, evaluate the level of automation that best suits your business needs. Fully automated machines can greatly enhance productivity and reduce labor costs, but there are also semi-automatic options that may better fit smaller operations. Furthermore, think about the materials you intend to use—whether you require the flexibility to work with different grades of cardboard or the ability to produce custom box sizes. Understanding these key factors not only helps in choosing the right machine but also ensures that your packaging line runs smoothly and efficiently.

Types of Cardboard Box Machines: A Comprehensive Overview

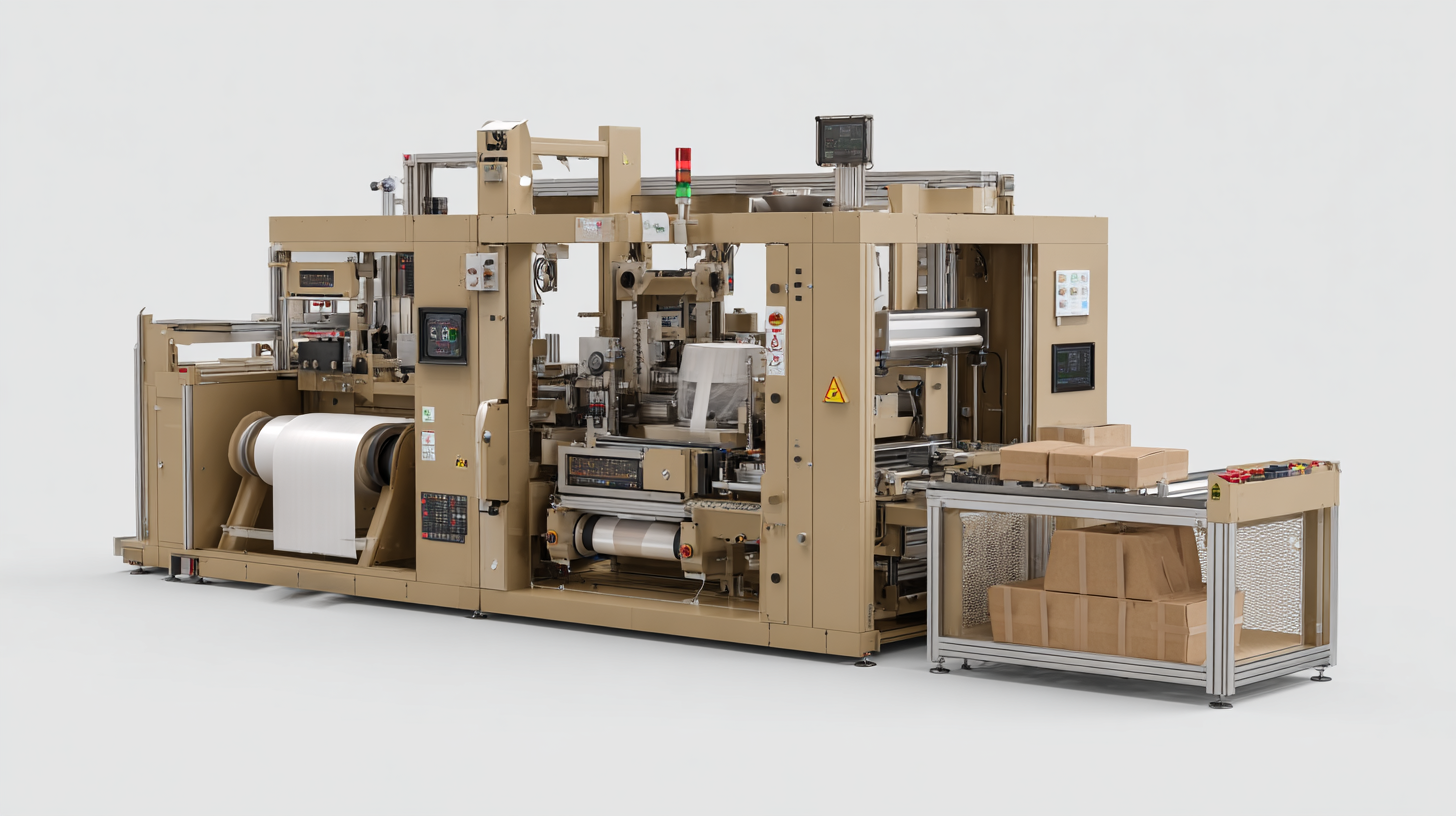

When selecting the best cardboard box machine for your packaging needs, it's crucial to understand the various types available in the market. There are primarily three categories of cardboard box machines: traditional folder-gluers, auto-boxing machines, and die-cutters. Each type serves distinct purposes and offers different production speeds and efficiencies. For instance, according to a recent industry report by Smithers Pira, the global cardboard box machinery market is projected to grow at a CAGR of 4.2% from 2021 to 2026, driven by the rising demand for efficient packaging solutions.

To make an informed choice, consider the specific requirements of your packaging operations. Traditional folder-gluers are suitable for smaller production runs, while auto-boxing machines excel in high-speed production, making them ideal for large-scale operations. Die-cutters offer enhanced design flexibility for custom boxes but typically come with a higher initial investment.

Tip: Before purchasing, assess your production volume and box design complexity to align your machine choice with your operational needs. Additionally, ensure the machine's compatibility with your current workflow to maximize efficiency. By understanding these types and their applications, you can make a more strategic choice that aligns with industry trends and your business objectives.

Evaluating Machine Features: What Makes a Cardboard Box Machine Stand Out

When selecting a cardboard box machine tailored to your packaging needs, understanding machine features is crucial for making an informed decision. Not all machines are created equal; features such as speed, automation level, sizing capabilities, and design flexibility define how well a machine can adapt to your specific requirements. For example, a machine that can handle a variety of box styles and sizes can significantly enhance production efficiency, allowing businesses to respond quickly to changing market demands.

Moreover, the integration of advanced technologies, including artificial intelligence and machine learning, is transforming the effectiveness of cardboard box machines. These innovations enable smarter decision-making processes, improving both production rates and quality control. By evaluating these features and trends, manufacturers can choose equipment that not only meets their immediate packaging needs but also supports sustainable practices through enhanced operational efficiency. As the folding packaging machine market is projected to experience substantial growth, understanding these characteristics will become increasingly important for businesses aiming to maintain a competitive edge.

Cardboard Box Machine Features Comparison

Cost-Effectiveness vs. Quality: Making the Right Investment

When selecting a cardboard box machine for your packaging needs, the balance between cost-effectiveness and quality is paramount. According to a recent report by Smithers Pira, the global corrugated packaging market is expected to reach $350 billion by 2025, highlighting the growing demand for efficient and reliable packaging solutions. Investing in a high-quality cardboard box machine may present a higher upfront cost, but it can significantly reduce long-term operational expenses through enhanced production efficiency and lower waste rates.

Tip: Prioritize machines that offer versatile capabilities to handle various box styles and sizes, ensuring flexibility in your production line. This adaptability can lead to cost savings as you avoid the need for multiple machines for different packaging requirements.

Cost-effectiveness does not solely rely on the purchase price; consider lifespan, maintenance costs, and energy efficiency. The Machinery Research Group reports that businesses can save up to 20% on energy costs with modern, energy-efficient models. Therefore, a comprehensive evaluation of a machine's total cost of ownership is essential for making a smart investment.

Tip: Conduct a thorough ROI analysis that includes not just purchase and operational costs but also potential savings from improved quality and reduced waste to make an informed decision.

How to Choose the Best Cardboard Box Machine for Your Packaging Needs: Insights & Trends

| Dimension | Description | Cost-Effectiveness (1-10) | Quality (1-10) | Investment Viability |

|---|---|---|---|---|

| Machine Speed | Measures the number of boxes produced per minute | 8 | 7 | Good |

| Energy Efficiency | Evaluates power consumption relative to output | 7 | 8 | Excellent |

| Maintenance Costs | Annual costs related to upkeep of the machine | 6 | 6 | Moderate |

| Flexibility | Ability to produce different box sizes and designs | 9 | 9 | Highly Viable |

| User Interface | Ease of operation and user-friendliness of the controls | 8 | 8 | Good |

Emerging Trends in Packaging Technology: Future-Proofing Your Business

In the ever-evolving landscape of packaging technology, staying ahead of emerging trends is essential for businesses looking to future-proof their operations. Recent advancements point toward a growing preference for sustainable materials, with cardboard becoming increasingly favored due to its recyclability and lower environmental impact. Companies are now integrating smart technologies into their packaging solutions, such as IoT-enabled boxes that can monitor conditions during transport and maintain product integrity, offering enhanced efficiency and traceability.

Moreover, the shift towards e-commerce has necessitated the development of innovative packaging designs that not only protect products but also enhance user experience. Customization is key in this regard, as brands seek to provide personalized packaging solutions that resonate with consumers. Automation in box production is also on the rise, allowing for faster turnaround times and greater flexibility in meeting diverse packaging needs. By embracing these trends, businesses can not only streamline their operations but also align their practices with the values of modern consumers, ensuring long-term success in a competitive market.